Code 49 is an early high-density stacked (combining one-dimensional and two-dimensional) barcode developed by Intermec in the late 1980s. It segments data into multiple rows, allowing higher data capacity and a more compact structure compared to traditional 1D barcodes.

Code 49 is unique because it allows an impressive amount of data to be encoded in a relatively small area. Unlike some of its linear predecessors, Code 49 stacks multiple rows of data, making it highly efficient for labeling small products, pharmaceutical items, and more. This higher density of information is precisely what sets Code 49 apart.

1. The Basics of Code 49 Barcode

1.1 What is Code 49 Barcode?

Code 49 is a high-density, multi-row barcode symbology designed to encode a large amount of alphanumeric and special character data. Developed in the 1980s, it was one of the first barcodes capable of handling extended data formats while maintaining a compact size. Its unique design allows for efficient use of space, making it ideal for applications where space is limited, but data requirements are high.

-

Key Features

-

High Data Capacity: Supports more characters than traditional 1D barcodes.

-

Compact Design: Suitable for small packaging or products with limited space.

-

Error Detection: Includes mechanisms to verify data integrity.

-

-

Use Cases

Code 49’s unique features make it ideal for applications requiring compactness and high data density, such as electronics, pharmaceuticals, and logistics.

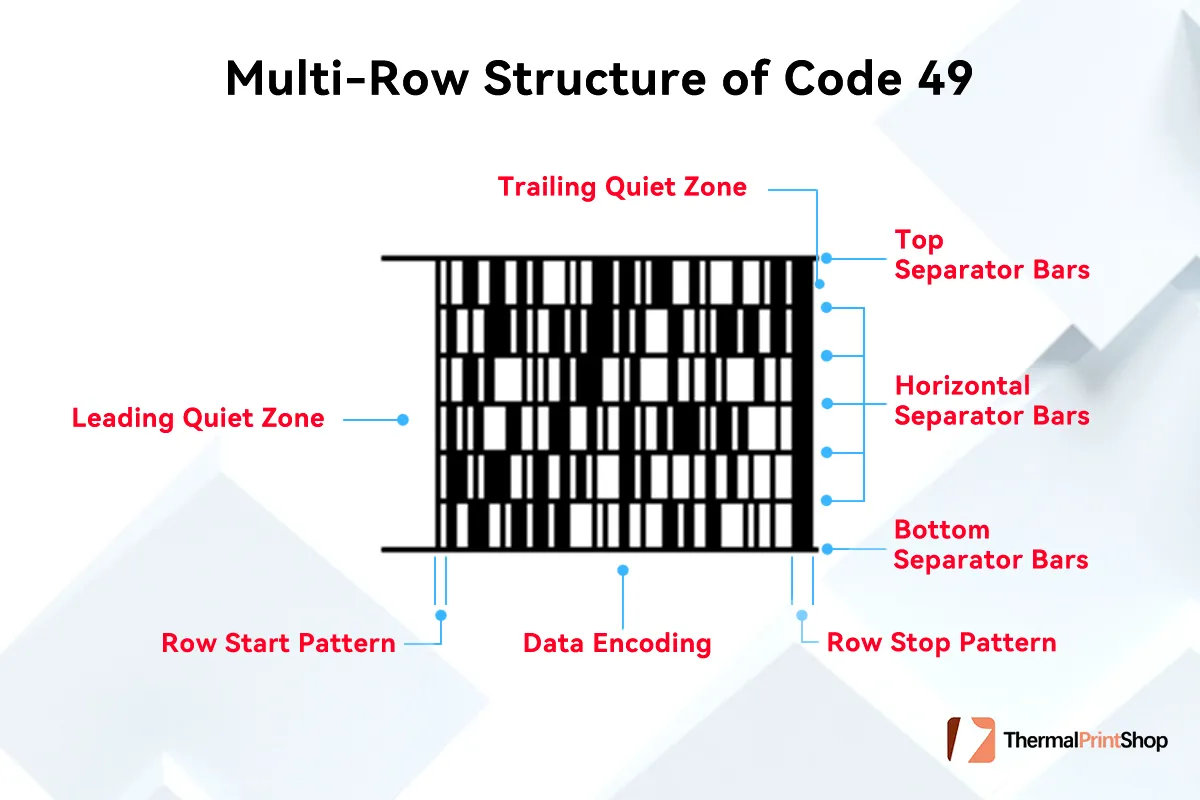

1.2 Multi-Row Structure of Code 49

Code 49 departs from the single-row format of traditional barcodes by stacking multiple rows of data. Each row is encoded in a way that is both compact and highly readable by specialized scanners. This innovative layout allows Code 49 to fit significant data into a relatively small label space. Whether you need to store serial numbers, batch codes, or even short text strings, Code 49’s multi-row design provides a convenient way to pack in more information without overcrowding the label.

A Code 49 barcode comprises 2 to 8 rows, each dynamically adjusted based on the data volume. Each row is structured with precision, ensuring data integrity and readability. Here’s a detailed breakdown of its elements:

-

Quiet Zones

-

Leading Quiet Zone: A blank space preceding the row start pattern.

-

Trailing Quiet Zone: A blank space following the row stop pattern. Quiet zones ensure the scanner can properly identify the start and end of the barcode.

-

-

Row Start and Stop Patterns

-

Row Start Pattern: Consists of a 1X bar followed by a 1X space, marking the beginning of each row.

-

Row Stop Pattern: A 4X bar signals the end of each row.

-

-

Data Encoding

-

Each row contains 4 symbol characters, encoding 8 ASCII characters in total.

-

The last character in each row is a row check character, ensuring error detection for data accuracy.

-

If fewer than 8 data characters are available in a row, placeholder characters fill the remaining space.

-

-

Separator Bars

-

Rows are divided by horizontal separator bars, ensuring clarity and preventing data misinterpretation.

-

The top and bottom separator bars extend into the quiet zones, framing the entire barcode for improved readability.

-

Internal separator bars, however, remain shorter and confined to the row boundaries.

-

-

Encoding Precision

-

Each row is encoded using 18 bars and 17 spaces, maintaining a consistent structure across the symbol.

-

1.3 Encoding Capacity and Character Sets

Code 49 supports a full ASCII character set, including letters, numbers, and special characters. It uses a combination of variable-width bars and spaces for encoding, allowing it to store up to 81 characters in a compact format.

This wider range of characters is especially beneficial in industries like healthcare, where complex data points (including text-based patient or product information) must be encoded accurately. The maximum data capacity can span dozens of characters, giving Code 49 a significant advantage over other linear barcodes that can only store smaller amounts of information.

-

Key Encoding Characteristics:

-

Each row encodes exactly 18 bars and 17 spaces, ensuring consistent readability.

-

Placeholder characters are used to fill out rows with fewer than eight data characters.

-

Code 49’s unique multi-row design allows it to hold up to 49 characters in total, distributed across its rows.

-

1.4 Error Correction and Readability

To read Code 49 barcodes, scanners must be equipped with software capable of decoding stacked symbologies. Many modern barcode scanners support Code 49, but older or basic models may require updates or specific configurations.

One of the biggest challenges with barcodes is ensuring they can be read reliably, even in harsh environments or after light damage. Code 49 addresses this by incorporating features that allow for error detection and correction, helping scanners identify the intended data despite minor printing inconsistencies or label wear. As a result, the readability of Code 49 remains high in real-world conditions, reducing the likelihood of scanning errors and misreads.

2. Key Advantages of Code 49

Code 49 is a stacked linear barcode symbology that offers several notable advantages:

-

Higher Data Capacity By stacking multiple rows of data, Code 49 can encode significantly more information than traditional one-dimensional barcodes (e.g., Code 39), making it a good choice for applications requiring larger amounts of data in a smaller space.

-

Compact Size Thanks to its stacked structure, Code 49 can pack a large amount of alphanumeric data into a relatively small label area. This makes it suitable for situations where space is limited, such as on small product labels or electronics components.

-

Variable Length Code 49 supports variable-length data, allowing flexibility in encoding different sizes of information without wasting space or needing to redesign the symbol layout.

-

Good Readability Despite its higher density, Code 49 is designed to be reliably scanned by standard laser or CCD-based barcode readers (provided the reader is compatible with stacked symbologies). This balance of density and readability makes it practical for many data-intensive applications.

-

Versatile Data Encoding Code 49 can encode a combination of alphanumeric characters and some special characters, which is beneficial for industries that require both letters and numbers—such as manufacturing, healthcare, or warehousing.

-

Error Detection and Correction Code 49 includes mechanisms for error detection and correction, improving reliability in data scanning and reducing errors.

Although Code 49 is not as commonly used today as more modern 2D symbologies (like Data Matrix or QR codes), its ability to hold more data than classic 1D barcodes still makes it a viable option where a compact, stacked linear solution is preferred.

3. What are the applications of Code 49 barcodes?

Due to Code 49’s ability to encode a large amount of information within a limited space, it is especially well-suited for applications requiring detailed data on small labels. Below are some typical use cases:

3.1 Industrial Manufacturing and Parts Tracking

-

In sectors such as electronics, machinery, and automotive, small parts often require multiple data fields (e.g., batch number, serial number, production date).

-

Code 49’s high-density format enables a large amount of information to be encoded in a relatively small area, aiding in production tracking and quality management.

3.2 Logistics and Transportation

-

In air, sea, and land freight, shipping labels often contain detailed data such as sender/receiver info, contents, and batch numbers.

-

The stacked structure of Code 49 can reduce label size while still accommodating rich data, providing convenience for package tracking and sorting.

3.3 Defense and Military Sectors

-

Military equipment and supplies often require rigorous traceability, including model numbers, batch codes, and possibly encrypted data.

-

Code 49 offers high data capacity and compactness, making it suitable for labeling munitions, gear, and spare parts for efficient tracking and inventory management.

3.4 Medical Devices and Pharmaceutical Traceability

-

The pharmaceutical and medical device industries require strict batch and expiration tracking, often involving extensive information.

-

Code 49 can compress necessary data into small spaces, supporting accurate traceability for drugs, samples, and devices.

3.5 Small Electronic Products or Circuit Board Labeling

-

Items like chips and PCBs (printed circuit boards) are physically small but need to carry detailed information (e.g., serial numbers, manufacturer details, production dates).

-

Code 49 makes it possible to encode this data in limited space, facilitating later tracing and quality control.

4. Best Practices for Implementing Code 49

While understanding the basics, advantages, and applications of Code 49 provides a solid foundation, putting this barcode into practice involves a few additional considerations. From creating a well-structured design to ensuring reliable scanning, here are some best practices to guide you:

4.1 Design and Layout

-

Quiet Zones: Reserve enough white space (quiet zones) around the barcode. Insufficient quiet zones can lead to scanning failures.

-

Module Size and Density: Determine the right module width and height to balance data density with readability. If too small, the bars may blur when printed; if too large, you lose the compact advantage of Code 49.

-

Orientation and Placement: Consider how the barcode will be oriented on the product or label. Align it in a way that aids both printing and scanning, and ensure it won’t be obscured by other design elements.

-

Barcode Generation Software: Use specialized software that adheres to official Code 49 guidelines. This ensures compliance with standards for encoding and symbol structure.

4.2 Printing Considerations

-

Printer Type: Thermal transfer printers are commonly recommended for high-density barcodes. They offer the precision and resolution needed to maintain clear bar boundaries.

-

Ink and Substrate: High-contrast printing (typically black ink on a white or light-colored background) is critical for scanner accuracy. If your application involves harsh conditions (e.g., chemicals, extreme temperatures), opt for durable label materials and ink formulations.

-

Resolution: For Code 49, especially at high densities, a higher DPI (dots per inch) setting is crucial. This prevents the bars from merging or losing definition, which can greatly reduce scanning success.

-

Testing and Quality Control: Regularly inspect printed samples with a verifier or dedicated scanner to confirm the barcode meets your quality and readability standards.

4.3 Scanning and Reader Compatibility

-

Scanner Support: Not all scanners natively support Code 49. Check if your existing 1D or omnidirectional scanner can decode Code 49 or requires firmware upgrades.

-

Optimal Scanning Conditions: Train end-users on proper scanning techniques. High-density codes may need the scanner to be positioned at specific angles or distances to capture data accurately.

-

Environmental Factors: Consider environmental lighting, glare, and the barcode’s physical placement. Excessive reflections or low light can hamper the decoding process, so ensure that scanners have suitable lighting or that barcodes are placed in well-lit areas.

4.4 Integration into Existing Workflows

-

Software Compatibility: Make sure your warehouse management system (WMS) or enterprise resource planning (ERP) software supports Code 49. If not, verify whether plug-ins or extensions are available.

-

Labeling Standards and Regulations: Certain industries, like defense or medical, have strict labeling guidelines. Align your Code 49 usage with any applicable regulations to avoid compliance issues.

-

Updates and Maintenance: Keep an eye on technology advancements. If newer scanning or printing technologies become available, evaluate whether transitioning away from or supplementing Code 49 is beneficial.

By taking these practical factors into account—design, layout, printing quality, and scanner compatibility—you can effectively integrate Code 49 into your operational environment. Whether you’re labeling small electronics or managing defense logistics, following these best practices helps ensure that Code 49’s compact, data-rich format delivers reliable performance.

5. Conclusion

By now, you’ve gained a solid understanding of Code 49—how it’s structured, how it encodes data, and the key reasons it emerged as a high-density, space-saving barcode. Although PDF417, Data Matrix, QR Code, and other 2D barcodes have become the dominant choices thanks to their advanced error correction and scanning versatility, Code 49 still occupies an important niche.

Its backward compatibility with 1D scanning technology and its ability to fit substantial information into a small footprint make Code 49 an enduring option for specific labeling needs. Whether you’re dealing with industrial manufacturing, logistics, defense, medical applications, or small electronics labeling, Code 49 remains a practical choice when strict size constraints or existing 1D workflows rule out bulkier or more complex solutions.

About the Author: Leo

Head of Product Innovation, shares expert insights on barcode printing solutions, helping businesses find reliable and cost-effective products.

some related articles

Barcodes have become an indispensable tool for businesses across the world. They enable quick and [...]

A QR Code (Quick Response Code) is essentially a two-dimensional barcode that can store information—like [...]

Barcodes have become an essential part of daily life, transforming the way businesses manage data, [...]